Services

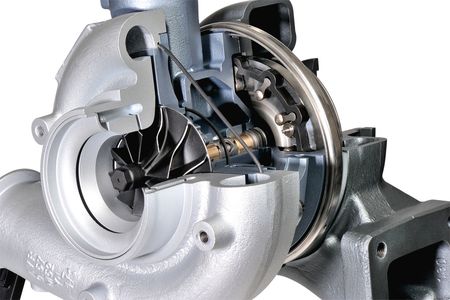

Turbo Upgrades

PT Turbo offers a large range of turbo upgrades which can have a dramatic improvement on your vehicles overall BHP and performance. Alongside our hybrid turbocharger upgrades we also offer genuine direct replacement turbos. Take a look at what turbo upgrades we offer below and if you're unsure of anything we are more than happy to help.

Compressor Side Turbo Upgrades

Fitment of Larger Compressor Wheel

A larger compressor wheel will allow the turbo to flow more air. More airflow, as we know, equals more power (with the correct modifications and mapping)! Our upgraded turbochargers usually feature the fitment of larger compressor wheels than standard. A lot of our turbochargers feature our own, unique, design of billet compressor wheel. The compressor wheels are CNC machined from a forged billet of aluminum to our own specification and dimensions ensuring that the performance lives up to our high standards. Utilizing forged billet aluminum compressor wheels as opposed the traditional cast aluminum items allows us to not only increase the strength of the wheel (very important when the blade tips on a compressor wheel can see supersonic speeds on some applications) but also, through clever design, reduce the weight. This transmits as improved turbocharger response over cast compressor wheels. The compressor cover will need Re-Profiling and the Compressor Backplate may well need modifying at the same time. The fitment of a larger compressor wheel can be a very effective upgrade and it's all machined in-house meaning we can get your upgraded turbo back to you faster.

Re-Profiled Compressor Cover

A Re-Profiled Compressor Cover allows the fitment of a larger compressor wheel which is an essential part of the upgrading process. The bore of the housing is enlarged to accommodate the new, larger wheel and the profile reshaped to match. All this is done whilst maintaining a strict tolerance between the wheel and housing to optimize efficiency of the turbocharger. A Ported Shroud Conversion can potentially be added at the same time if required. To find out further information about a ported shroud conversion please scroll further down the page.

Modified Compressor Backplate

Modifying the Compressor Backplate allows the fitment of a Larger Compressor Wheel which is an essential part of the upgrading process. The backplate houses the recess in which the compressor wheel sits; a larger compressor wheel will require the backplate opening to suit. As with everything done here, a tolerance is closely followed in the name of quality, efficiency and performance.

Turbine Side Turbo Upgrades

Fitment of a Larger Turbine Wheel

The Fitment of a Larger Turbine Wheel is, in theory, much the same as the Fitment of a Larger Compressor Wheel it allows the turbocharger to increase the airflow resulting in an increase in power (with the correct modifications and mapping). It does this in two different ways. Firstly, the larger turbine wheel can drive the compressor wheel harder resulting in more airflow, and with more airflow equals more power potential. Secondly, the larger wheel reduces backpressure within both the turbine housing and manifold in much the same way as a Cutback would when applied. This reduction in backpressure If you want to find out more regarding fitment of a larger turbine wheel or some of the following upgrades we offer, do not hesitate to ask, email or call us today.

Re-Profiled Turbine Housing

Machining of the Turbine Housing allows a larger turbine wheel to be fitted which can be an important part of the upgrading process. The bore of the housing is enlarged to accommodate the new, larger turbine wheel and the profile is reshaped to match. This is all on-going while we are maintaining a strict tolerance between wheel and housing to optimize efficiency for your turbo.

Turbine Wheel Cutback

Turbine Wheel Cutback is one of many machining processes which is carried out in our machine shop. A turbine wheel cutback enables the turbo to increase its power output by reducing back pressure. This process however does remove some blade material from the turbine wheel which can, in some instances, result in a slight reduction in turbocharger response.

Porting & Polishing Turbine Housing

Porting and polishing the Turbine Housing helps provide maximum gas flow, thus improving efficiency. It is often and most likely to be carried out on the turbine housing inlet but it may also possible to carry this out to the wastegate if your vehicle is experiencing ‘boost creep’. Flanges can also be gasket-matched if required to optimize flow.

Turbo Maintenance

Turbocharger maintenance can be a headache, especially because figuring out the problem in the first place can be quite a puzzle. It is our goal to make this process easy and affordable for you. We are different because we genuinely care about your turbocharger, and we search for the best ways to get you back on the road as quickly as possible.

Turbo Rebuilds

We can rebuild almost any make and model of turbo. A standard rebuild is one in which no internal hard parts (turbine shaft/wheel, compressor wheel, bearing housing) need repair or replacement. A standard rebuild consists of a complete balance, a rebuild kit with new thrust parts (if applicable), and thorough part cleaning. Your turbo will look like new when you take it back from our facility.

High Speed VSR Balancing

If you want to have your turbocharger components balanced, you can bring it to us. We do not need the complete turbo in order to balance it, so you just have to bring us the compressor wheel, turbine shaft, lock nut, bearing housing, and the thrust parts.

Turbo Repairs

If your turbo has failed, PT Turbo's repair service is an excellent choice to get you back on track quickly, usually at a lower cost than buying new or having a re-manufactured turbo would cost you.

Keeping your turbo clean

Regular turbo cleaning is important, so feel free to have yours cleaned at our facility.

Ceramic Coating

With our turbos we offer Ceramic Coating technology for all turbochargers as well as turbo related components such as manifolds, exhaust headers, exhaust down pipes, external wastegates. All of our Ceramic Coating applications are carried out by Turbo-Hot. Turbo-Hot is the market leader within the ceramic coating industry and have developed a range of ultra-high performance plasma-sprayed ceramic coatings to protect such components from effects of fire, heat, wear corrosion and abrasion. Ceramic Coating reduces under hood temperatures by up to 122 degrees Fahrenheit as well as increasing the engines performance and extending the life of components and therefore enhancing engine reliability.

Ceramic coating is available in a range of colours and it it comes down to personal preference and does not effect the performance: Diamond Black, Graphite Grey, Sterling Silver. Enquire today and ask to view the range of colours.

Get a free quote today!

Better yet give us a call or come see us in person!

We love our customers, so feel free to give us a call, or come visit during normal business hours.

Business Hours

Open today | 09:00 am – 05:00 pm |

Monday - Friday: 8am - 5pm

Saturday & Sunday: Closed